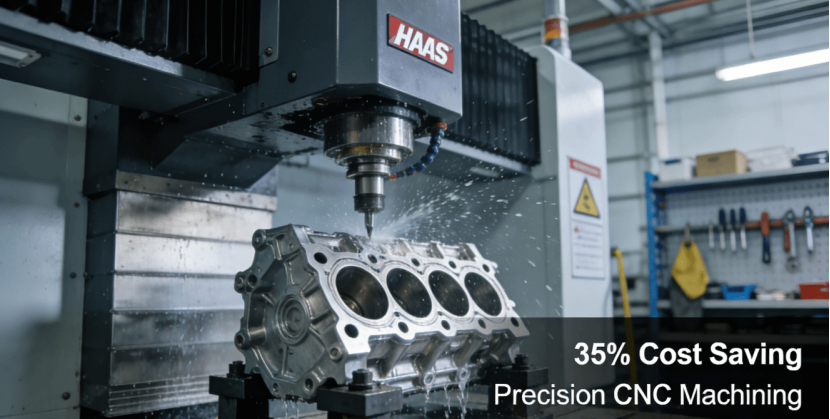

The manufacturing industry is facing severe problems in the production of engine blocks due to high costs and low precision, which negatively impact efficiency in the automobile and aerospace industries. At the root lies inefficient conventional machining, full of errors that result in cost overruns and delays in project execution.

The article examines how precision CNC machining technology, combined with online services, addresses these problems by improving accuracy and controlling expenditures. The subsequent sections will explain the main technologies and practical methods in detail.

What is Precision Manufacturing Technology and Its Application in Engine Block Machining?

Precision Manufacturing Technology constitutes the utilization of highly advanced processes capable of very tightly controlling machinery tolerances and producing parts with high repeatability. By way of illustration, in the case of engine blocks, components are manufactured to extremely close tolerances, for example, only ±0.005mm, which is a major factor determining performance and durability. The use of precision CNC machining in the production of engine blocks has several benefits, such as less raw material wastage, higher efficiency, and greater confidence in product reliability.

Several automotive manufacturers have claimed an increment in their productivity by as much as 20% after they have changed to these methods, which was the result seen where CNC Engine Block Machining capacity lowering the production cycles.The guidelines from the International Society for Precision Engineering (ISPE) articulate that these technologies reduce deviations and optimize resource utilization, thus directly contributing to sustainable manufacturing. For further information, refer to the CNC Engine Block Machining Guide.

Basics in Precision Manufacturing

This system is based on computer-controlled machines that can carry out challenging geometries in a much automated fashion, hence leaving little room for human error and product uniformity from batch to batch.

Advantage in Engine Block Production

The key benefits include high accuracy in cylinder bore machining, where roundness can be maintained within 0.005mm, and reduced lead times due to automation.

- Case Example: Implementation in the Automotive Industry

One leading car manufacturer has utilized precision machining to shave 25% off the weight of engine blocks without compromising their structural integrity-a development with significant implications for fuel efficiency and emissions.

- Standards and Compliance

Conformity to international standards, such as those from ISPE, ensures that precision manufacturing meets global benchmarks of quality, thus easier to adopt across industries.

How to Choose the Optimal CNC Engine Block Machining Tools?

Selecting the right tools for CNC engine block machining tooling is a very important thing if we want to be efficient and save money. To this end, factors such as what materials the tools can be used with, how long the tools will last, and the ways of machining should be considered. For instance, PCD (Polycrystalline Diamond) tools are very suitable for aluminum alloys because they are extremely resistant to wear, thus they will last 5, 8 times longer than carbide tools. This is in line with the concept of Industrial Business Solutions that direct their efforts towards finding ways to reduce operational costs.

The Society of Automotive Engineers (SAE) in their research work state that if you choose the right set of tools, your device will be running for a longer period without a breakdown, and also more project deliveries will be successful. A case of a company is narrated whereby they experienced a 15% decrease in tooling costs by the adoption of a system that was guided by data for tool management. It is essential to use the right tools for a particular material of the engine block, ceramic tools can be used for cast iron to give the advantage of high, temperature resistance, on the other hand, carbide works well with high speed steel (HSS) applications.Employing parameter databases for speeds and feeds in cutting will be of great help in prolonging the life of the tool; to illustrate, the cutting of gray cast iron is generally done at speeds of 80, 120 m/min so as to achieve a good compromise between productivity and tool wear.

Which Materials Are Most Suitable for CNC Engine Block Manufacturing?

The selection of materials largely determines the capabilities, weight, and expenses of making an engine block. CNC engine block materials such as Aluminum Alloys, and Cast Iron are typical, each having different benefits. For Aerospace Manufacturing Parts, the use of light materials such as aluminum, magnesium alloys is mainly because of their high strength, to, weight ratio. Material optimization, according to The International Union of Materials Research Societies (IUMRS), can lead to increased durability by as much as 30% even in severe environments. Custom Parts Manufacturing usually involves a material choice that is determined by the application in a very specific way; for example, ductile iron was used in heavy machinery in order to get better vibration damping.

| Material Type | Strength (MPa) | Weight Reduction | Ideal Applications |

| Aluminum Alloy | 250-400 | 30-40% lighter than cast iron | Passenger vehicles, aerospace |

| Gray Cast Iron | 200-300 | Minimal | Commercial trucks, industrial equipment |

| Ductile Iron | 400-600 | Moderate | Construction machinery, heavy-duty engines |

| Magnesium-Aluminum Alloy | 300-500 | 15-20% lighter than aluminum | High-performance sports cars, EVs |

Aluminum alloys provide better thermal conductivity, reducing overheating risks, while cast iron offers excellent wear resistance for high-stress applications.Material selection directly affects manufacturing costs; for example, aluminum may have higher raw material costs but lower machining expenses due to easier processing.

What Are the Key Technologies in CNC Machining Cylinder Heads?

CNC machining cylinder heads is a highly intricate operation that includes modifying combustion chambers and accurately controlling valve seats, thus directly influencing vehicle performance. Similarly, in Medical Device Production, such exactness ensures that the components are safe, and therefore, they can only vary in size by 0.008mm at most. The International Medical Device Regulators Forum (IMDRF) states that the use of advanced machining methods such as 5, axis milling allows the manufacture of geometrically complex parts necessary for airtight seals. Rapid Prototyping Services greatly shorten the development cycles of experiments with cylinder head models; for example, the automotive industry has opted for this mode to chop the vehicle development time by 25%.

The use of finish milling in the process results in a surface with a roughness of no more than Ra 0.8μm, thus making it harder for carbon to stick and combustion to be at its best. Leakage can be averted if coaxiality errors are not more than 0.01mm, which is quite a feat considering that it is normally done by using highly specialized tools and very strict quality management processes.

How to Reduce Engine Block Manufacturing Costs Through Online CNC Machining?

Using CNC machining online services can help save a lot of money by offering real, time quoting, automated processes, and less hidden costs. The cost structure for engine block machining is dominated by tool usage cost (around 15, 20% of total costs) and equipment depreciation, which online platforms through lean production methods facilitate very efficiently. For example, Online CNC machining services allow immediate communication of the design changes, thus saving as much as 40% of the time before production starts. ISO 9001, IATF 16949, and AS9100D certifications are standards for quality, ensuring minimal rework and the reduction of costs related to rework. Statistics indicate that CNC engine block machining cost can be cut by 20, 35% by way of digital integration, which is evident in the cases where online monitoring systems have been able to spot early the anomalies.

Advantages of Online Platforms

These services offer transparency in pricing, with automated DFM (Design for Manufacturability) analysis helping clients avoid design flaws that increase costs.

Cost Optimization Techniques

Process merging and tool life management are key; for example, combining roughing and finishing operations can save $35 per unit in some cases.

- Implementation Steps

Clients can upload CAD files for immediate quotes, followed by engineer reviews to align specifications with budget constraints.

- Quality Assurance

Online systems incorporate real-time sensors to monitor machining parameters, ensuring consistency and reducing error rates.

Conclusion

In short, precision CNC machining technology helps to solve the engine block production challenges by improving the use of tools, materials, and online services, thus resulting in the overall cost reduction and industrial performance improvement. Companies are advised to get hold of the specialists for customized CNC machining services that will pave the way for the simplification of their manufacturing operations.

Author Profile

This article was authored by precision manufacturing specialists at JS Precision, with extensive industry experience dedicated to delivering high-quality industrial solutions.

FAQs

Q: Is precision CNC machining into the production of medical devices?

A: Yes, precision CNC machining for medical devices is suitable as it ensures components of high tolerance to meet safety standards. The typical lead time usually ranges from 5-15 days to ensure compliance in the process.

Q: How does online CNC machining ensure quality?

A: Online services utilize automated inspections and certifications such as ISO 9001, ensuring that real-time monitoring reduces errors and enhances reliability.

Q: What are the most common materials in engine block machining?

A: Examples include aluminum and cast iron. Aluminum is light in weight, thus possessing certain advantages in motor car applications, while cast iron gives strength for heavy machinery, completed according to customer’s or project requirements.

Q: What are the main difficulties that appear in the CNC machining of cylinder heads?

A: Challenges include valve seat accuracy and thermal deformation management, issues usually resolved through special tools and cooling technologies to allow sealing.

Q: In what ways is it possible to evaluate the costs of CNC engine block machining?

A: Costs are material, tooling, and volume-dependent; online quotation tools with real-time analysis help in optimizing budgets in view of specific needs.