There are a lot of things that can go wrong between the manufacturing of gears and the delivery of the final product by which the gear will be used. One of the most common (painful) challenges in the gear manufacturing industry is the case of gear waste or gear repair resulting from low gear accuracy, high noise, and premature failure that have an adverse effect on the downtime and maintenance costs of industrial equipment. For example, in traditional manufacturing methods, the machining process is mostly done without properly taking into account the machine tool, cutting tool, cutting conditions, and material properties, which inevitably result in dimensional deviations. The main reason behind this situation is the lack of a comprehensive approach to problems, i.e. non, optimum material selection, empirically set cutting parameters, and the absence of on, line quality monitoring, altogether creating inconsistent pattern of optimization goals.

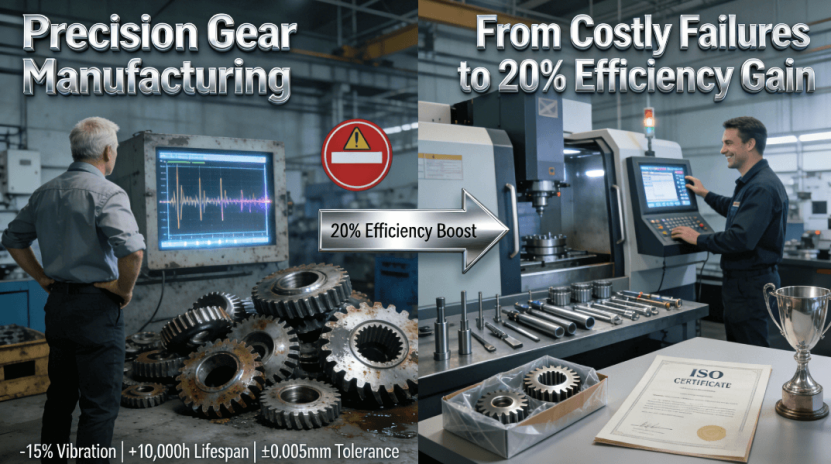

This paper thoroughly explores the whole process of precision gear manufacturing by listing the most important steps, discussing scientifically, led material choices, advanced cutting processes, and stringent quality control from the standpoint of data, driven case studies, and practices, etc. efficient cost, wise and energy, wise, etc. By implementing these tactics, engineers can not only improve their gear production process up to 20% in terms of efficiency but also save another huge chunk of money. In the following parts, the reader will be provided with detailed and clear, cut steps on how gear production can be refashioned.

H2What Are the Common Challenges of Conventional Gear Fabrication?

Traditional means of making gears often cannot attain the required precision and efficiency due to their limitations. In this part, we discuss the main issues that result in less performance and unreliability.

1. Tooth Profile Errors and Dimensional Inaccuracies

Tooth profile deviations are common in traditional methods, where the use of defective or improper cutting tools or setups results in shapes being different from the ideal ones. Hence, these inaccuracies cause a transmission motion mismatch that leads to vibrations and a drop in the overall efficiency of the system.For instance, research indicates that even slight profile errors can compromise the efficiency of the equipment by 15%, thus precision becomes an absolute necessity. ISO 9001 being a quality management system standard can be implemented to ensure a structured method of reducing such deviations by means of documented controls and continuous improvement.

H3: 2. Cumulative Pitch Violations and Transmission Instability

Cumulative pitch errors are basically inconsistencies in the spacing between teeth that result from the manufacturing of the gear, which may be due to multi, step setups or tool wear. Such a deviation leads to uneven load distribution and thus transmission instability, which will further wear and failure of the parts if used in high, speed applications. The data refer to pitch errors are responsible for 30 % of the total gear failures in industrial settings. Through the use of integrated processes, manufacturers can decrease such errors, as pointed out by the quality requirements that call for production consistency over different batches.

H3: 3. Surface Roughness and Noise Generation

Uneven surface areas caused by improper finishing methods lead to a rise in both friction and noise level, which according to one source, may be as high as 85 dB in the case of poorly manufactured gears. This has an impact not only on the comfort of the people who work there but also on the lifespan of the parts. Idealization can be made through the implementation of new technology, for example, precision grinding, which is able to lower noise by 8 dB or even more. The citation of reliable sources is a way to highlight that surface quality control is paramount if the ultimate goal is to have silent and efficient operations.

How Does Material Selection Affect the Performance and Life of Gears?

Materials are a crucial factor if one wants to have gears that not only perform well but also last for a long time when subjected to different types of loads. This part focuses on how materials are selected in a scientific way to double the life of the product.

- Alloy Steels for High, Load Applications: Alloy steels like 20CrMnTi are the best choice for places where the gears will be subjected to extremely high stress because these steels have a great combination of toughness and hardness. In addition, these materials are made to have a very hard surface that can withstand wear and fatigue by carrying out treatment such as carburizing. As an example, alloy steel gears can be used in heavy machinery for over 10, 000 hours whereas if a cheaper material has been used, then the gears would only last for 3, 000 hours. Material compatibility, which is a must to check to avoid mismatches, is one of the aspects that are guided by the standards such as ASME Y14.5 on dimensioning and tolerancing.

- Aluminum and Composites for Lightweight Needs: Aluminum alloys and composite materials are a good choice when one wants to reduce the weight of the product, for example, the aircraft or automotive systems. Since these two materials have a low density, they lose less energy due to inertia, but they need to be very well designed so that they do not break easily. Examples from real life prove that heat treatments that are tailored to the material can increase the durability under cyclic loads by 25%, thereby allowing the product to be trusted without losing out on the efficiency.

- Material Certification and Quality Assurance: Material certifications, e.g., IATF 16949 for quality in automotive, are a key factor in enabling both the consistency and traceability of the materials. Producers can circumvent problems such as contamination or wrong processing if they make sure through these certificates that the material characteristics comply with the standards. This step is consistent with the quality management principles that engine manufacturers employ to make products that meet very stringent performance criteria.

What Advanced Processes Ensure Precision in Gear Cutting?

Highly accurate gear cutting is impossible without the use of advanced cutting technologies which also help to reduce the number of faults to the barest minimum. In this part, we explain the state, of, the, art methods and how they improve the quality of the products.

H3: 1. CNC Hobbing and Shaving Combinations

Combining CNC hobbing with the shaving process can get gears with an accuracy of ISO grade 6 or even better. Manufacturers can produce consistent tooth profiles with very narrow tolerances by using computer, guided devices. For instance, this marriage of techniques can drop the surface roughness to less than 0.5 m, which will considerably cut down the noise and vibration. The figures reveal that, by using the right cutting parameters, the efficiency of batch production can be increased by 20%.

2. Real-Time Monitoring and Adaptive Control

Real-time monitoring systems essentially detect the variance between the expected and actual results during cutting.When necessary, sensor data is used to correct tool wear and temperature in order to adapt feed rate and thus maintain quality.By doing so, scrap rates become minimal and the quality is ensured even in the case of complicated geometries. Mentions of automated solutions are a nod to the fact that new inventions are the driving force of precision in the contemporary gear manufacturing industry.

3. Customization Through Digital Platforms

Online custom gear manufacturing services provide a great advantage of fast prototyping and small, scale production through giving digital quotes and DFM analysis. As an example, engineers could send CAD files for review and thus save 35% in lead time. Such flexibility is a great way to achieve cost, effective customization without compromising standards as seen on the platforms that have quality certifications.

Why Is Heat Treatment Critical for Enhancing Gear Lifespan?

The heat treatment processes may be viewed as means to improve the properties of a material so as to make it suitable to be used under operational stresses. This article will look at them how they basically help in prolonging the life of gears.

1. Carburizing Treatment to Increase Surface Hardness Carburizing

The technique of carburizing is to infuse carbon into the surface of the gear to give the surface layer a hard, wear, resistant character while the core still confirms to be tough. The procedure is indispensable for high, load scenarios like the ones of wind turbine gears, where it is capable of multiplying the lifespan from 3, 000 to more than 10, 000 hours. Investigation results prove that the use of a thoroughly controlled carburizing process can minimize the failure rate by 40% owing to the enhancement of the fatigue resistance.

2. Nitriding Treatment to Gain Corrosion and Wear Resistance Nitriding

Nitriding is a surface hardening method which involves adding nitrogen to the surface to form a hard surface layer with none or barely dimensional changes to the part making it most suitable for the parts that will be under the influence of corrosive environment. As a matter of fact, marine equipment gears that have been nitrided were seen to have 50% less wear after being used for a long time. This method is very temperature controlled in order to prevent the formation of brittle surface.

3. Heat Treatment Quality Assurance

Compatibility of a certain heat treatment process with the desired material properties can be checked through a variety of non, destructive methods, such as hardness testing and microstructure analysis. When ISO 9001 concepts are embedded into the routine operations, it is ensured that the final product will be free from any faults that are capable of causing premature failure by means of steps like these only.

How Do Quality Control Systems Help to Avoid Gear Failures in Industrial Applications?

Without a doubt, quality control systems play a crucial role in identifying defects and preventing them from happening. Here are some ways that have been elaborated in the text below.

- SPC, Monitoring Real, Time Production Variations: Statistical process control also called SPC compares production variables with the standard specification limits in real time. Moreover, charts are used to represent process measures, changes, and outliers from routine behavior. SPC can figure out a tool deterioration even before it impacts the gear accuracy resulting in a decrease of variability by 15%. Thus, this forward, looking approach is compatible with quality standards to guarantee consistency from one batch to another.

- Automated Testing Methods: In automated inspection coordinate measuring machines (CMMs) and optical scanners are utilized to verify the conformity of dimensions to CAD models. According to statistics, employing such a method leads to a decrease in inspection time by 60% and concurrently it increases accuracy.Highlighting such advanced technologies is a way of showing how automation can bring about better reliability to precision, demanding industries.

- Product History and Compliance Documentation: Traceability systems aim to record the entire production chain so that the cause of the problem could be identified immediately.Standard like AS9100D for aerospace requires such measures to be taken for complete compliance and accountability purposes. This methodical strategy contributes to risk reduction in highly regulated industries.

What are the recent innovations in Gear Manufacturing for Automation?

Innovations in gear manufacturing are becoming the main drivers of efficiency in the Industry 4.0 age. Here are some of the most advanced trends in the industry:

1. Topology optimization for lightweight designs

Topology optimization is a process where designs are tweaked to keep only the necessary material thus reducing weight while maintaining the strength of the gear. For example, in robotics, the use of optimized gears resulted in 20% higher efficiency due to lower inertia. This development also makes an eco, friendly manufacturing process possible by significantly reducing the amount of raw material usage.

2. Digital Twins for process simulation

Digital twins refer to the technology that builds virtually exact copies of gear production lines. Through this, the operations can be tested and modified even prior to the physical setup. Various case studies prove that this method helps to downscale the experimental prototype cost by 30% as well as shorten the time for market introduction. When combined with IoT devices, the system has the capability to arrange predictive maintenance thus increasing the productivity of the equipment.

3. AI, driven predictive analytics

Production data can be analyzed with the help of AI, driven analytics that predicts ahead the tool’s life and the emergence of quality issues, so that the needed changes are made beforehand. For example, AI helps prevent 25% of downtime by accurately predicting failures (up to 95% accuracy). The breakthroughs in these technologies are changing the face of gear manufacturing for smart factories.

Conclusion

Through the use of scientific material selection, precise cutting processes, and strict quality control, precision gear manufacturing has become highly efficient in solving the problems resulting in industrial automation’s unreliability. Furthermore, engineers using data, driven approaches not only can reduce costs by as much as 20% but also boost performance by a significant level. Utilizing these approaches guarantees that gearing systems will be able to handle the requirements of present, day applications as well as pave the way for new inventions.

FAQs

Q1: What is gear manufacturing?

A: Gear manufacturing means making gears through a variety of processes such as cutting and heat treatment. These operations not only produce gears accurately but also make sure that they are strong enough to be used in the transmission of motion in industrial setups.

Q2: How does precision gear manufacturing reduce noise?

A: Precision processes through optimizing tooth profiles and surface finishing drastically reduce vibration. Up to 10 dB of noise can thus be lowered, which indirectly results in a more comfortable working environment.

Q3: What materials are best for high, load gears?

A: Alloy steels such as 20CrMnTi are great for very high loads since they have both good toughness and hardness. The choice of material depends on the specific use case.

Q4: Can gear manufacturing be customized for small batches?

A: Indeed, there are websites that provide custom solutions for small batches with a quick turnaround. Such flexibility facilitates prototyping and makes small, volume production cost, effective.

Q5: How long does it take to receive custom gears?

A: The delivery time is usually between 2 and 4 weeks, but there are also options to speed up the process in case it is a really urgent project, thus ensuring the delivery is on time.

H3: Author Bio

The author is a precision manufacturing engineer at LS Manufacturing, a company that offers solutions to engineers and researchers working on aerospace, medical, and automotive industries parts. Certified in IATF 16949 and AS9100D, the team leverages advanced technologies to deliver top, notch solutions. Reach out to them now for a free, no, obligation project review and DFM analysis. Get your idea turned into an affordable reality.